Situation

From fashion and home textiles up to technical products - textiles made of polyester are used nearly everywhere. Various features such as high viscosity, good washing as well as wear resistance or high colourfastness accompanied by a low price have supported the material on its way to popularity. Therefore with more than 56,7 Mio tons much more polyester is produced than cotton (25,7 t). Still, some properties are not wanted - low wettability or a high tendency to build up electrostatic charges for example. Those are normally overcome by hydrophile or anti-static finishing agents that have one disadvantage: they disappear over time.

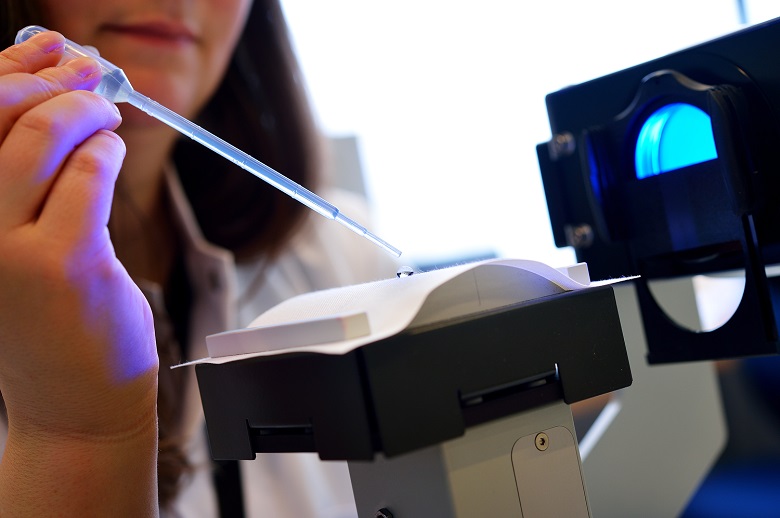

© Carlos Albuquerque

Project

The project is dedicated to developing enzymatic treatments for conventional as well as bio-based and biologically degradable polyester to reduce those unwanted properties on the long-term.

Benefit

SMEs of the whole textile value chain from fibre industry via textile production and dyeing factories up to manufacturers of workwear, sportswear and outdoor clothing will be able to use environmentally friendly procedures to functionalise their products. Therefore the door to a "green polyester community" is opened.

Beteiligte Forschungseinrichtung/en:

FTB - Hochschule Niederrhein, Fachbereich Textil- und Bekleidungstechnik

Institut für Umweltbiotechnologie, Universität für Bodenkultur Wien

Forschungsinstitut für Textilchemie und -physik, Uni Innsbruck

funding:

funding programme: BMWi/IGF

Project start: 01.01.2020

duration: 24 months

funding amount: 245 890 €

IGF-No. 259EN

projekt monitoring commitee:

Fibre manufacturer

Textile manufacturers

Membrane manufacturers

Textile machinery manufacturer

Enzyme developer

Textile finishing companies

Textile chemicals manufacturer

Finden Sie hier weitere interessante Inhalte